Syringe Mold /mold

Sirinjin da za a iya zubarwa sune mahimman kayan aikin da ake amfani da su a cikin tsarin masana'anta na sirinji, waɗanda ake amfani da su sosai a cikin allura da jiko a cikin masana'antar likitanci. Anan akwai wasu mahimman fannoni na ƙirar sirinji da za a iya zubarwa:

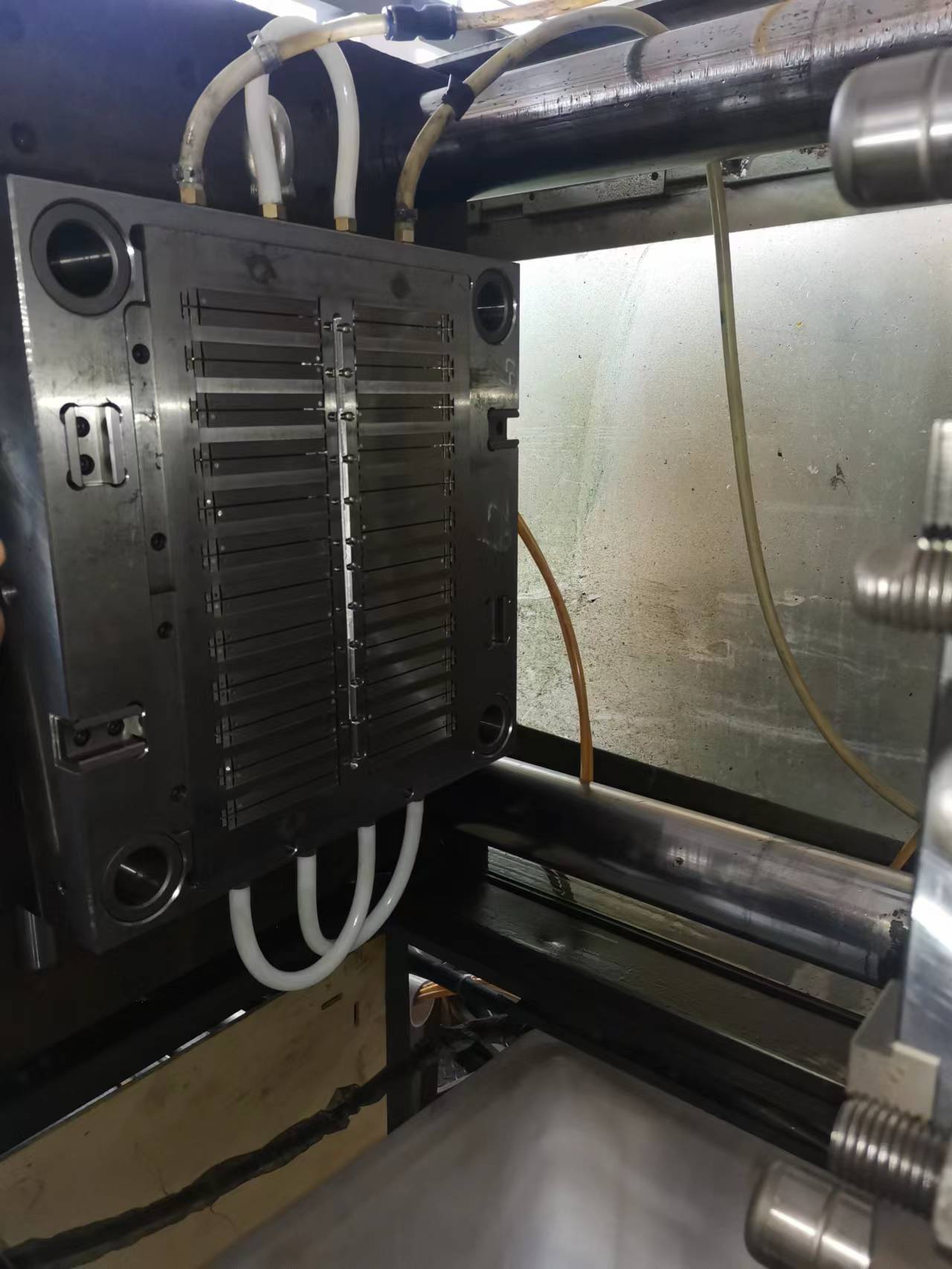

Ƙirar Ƙira: Ƙirƙirar sirinji mai yuwuwa an tsara shi musamman don ƙirƙirar siffa da fasalin da ake buƙata don taron sirinji. Yawanci, ya ƙunshi rabi guda biyu, alluran allura da ƙwanƙwasa, waɗanda aka haɗa su zama rami. Ana yin gyare-gyare na ƙarfe mai inganci ko aluminum don jure matsanancin matsin lamba da zafin jiki da ke cikin aikin gyaran allura.

Alluran Abu: Ana shirya ƙirar a cikin injin gyare-gyaren allura ta hanyar dumama albarkatun ƙasa (yawanci robobi na likita kamar polypropylene) har sai ya kai ga narkakken yanayi. Ana yin allurar narkakkar da aka yi a cikin rami mai ƙarfi ƙarƙashin matsi mai ƙarfi. Yana gudana ta tashoshi da ƙofofi a cikin ƙirar, yana cika rami kuma yana samar da sifar taron sirinji. Tsarin allurar ana sarrafa shi sosai don tabbatar da daidaito da daidaito wajen samar da sirinji.

Yin sanyaya, ƙarfafawa da fitarwa: Bayan an yi allurar kayan, narkakkar kayan yana sanyaya kuma yana ƙarfafa cikin ƙirar. Ana iya samun sanyaya ta hanyar haɗaɗɗun tashoshi masu sanyaya a cikin ƙirar ko ta matsar da ƙirar cikin ɗakin sanyaya. Bayan ƙarfafawa, ana buɗe ƙirar kuma an fitar da sirinji da aka gama ta amfani da na'ura kamar fil ɗin fitarwa ko matsa lamba na iska don tabbatar da aminci da ingantaccen cirewa daga ƙirar.

Ana aiwatar da matakan kula da ingancin a duk cikin tsarin masana'antu don tabbatar da cewa sirinji sun cika ƙayyadaddun da ake buƙata kuma suna bin ƙa'idodin likita. Wannan ya haɗa da duba ƙirar ƙirar ƙira, saka idanu sigogin allura da kuma binciken bayan samarwa na sirinji da aka gama don tabbatar da ingancinsu, aiki da amincin su.

Gabaɗaya, gyare-gyaren sirinji da za a iya zubarwa suna ba da damar samar da ɗimbin sirinji waɗanda za a iya zubar da su, wanda ke taka muhimmiyar rawa a yanayin kiwon lafiya. Samfurin yana tabbatar da cewa ana samar da sirinji koyaushe zuwa ƙayyadaddun bayanai da ake buƙata, saduwa da ƙa'idodin likita, da samar da ingantaccen aiki lokacin amfani da allura ko jiko.

| 1.R&D | Muna karɓar zanen 3D na abokin ciniki ko samfurin tare da buƙatun cikakkun bayanai |

| 2.Tattaunawa | Tabbatar da cikakkun bayanai game da abokan ciniki: rami, mai gudu, inganci, farashi, kayan abu, lokacin bayarwa, abu na biyan kuɗi, da sauransu. |

| 3. Sanya oda | Dangane da abokan cinikin ku sun tsara ko zaɓi ƙirar shawarwarinmu. |

| 4. Mold | Da farko Mun aika mold zane zuwa abokin ciniki yarda kafin Mu yi mold sa'an nan fara samar. |

| 5. Misali | Idan samfurin farko ya fito bai gamsu da abokin ciniki ba, muna canza ƙirar kuma har sai mun hadu da abokan ciniki gamsu. |

| 6. Lokacin bayarwa | 35-45 kwanaki |

| Sunan Inji | Yawan (pcs) | Asalin ƙasar |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM (Madubi) | 2 | Japan |

| Yanke Waya (sauri) | 8 | China |

| Yanke Waya (Tsakiya) | 1 | China |

| Yanke Waya (a hankali) | 3 | Japan |

| Nika | 5 | China |

| Yin hakowa | 10 | China |

| Latar | 3 | China |

| Milling | 2 | China |