Farji Speculum Mold don Amfanin Lafiya

Matsalolin mu na farji an yi su daidai don aikace-aikacen likita, suna tabbatar da samar da ingantattun na'urorin likitanci. Tare da mai da hankali kan daidaito da aminci, an ƙera ƙirar don saduwa da ƙayyadaddun ƙa'idodi na likita da samar da madaidaicin madaidaicin ƙirƙira na ƙirar farji da aka yi amfani da shi a gwaje-gwajen likita.

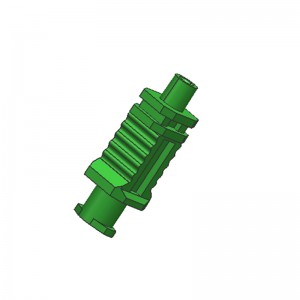

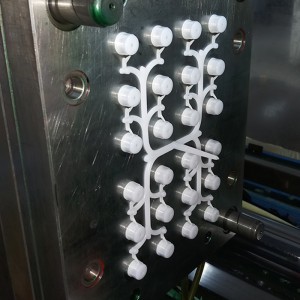

Wani nau'in nau'in nau'in nau'in nau'i na farji wani nau'i ne na musamman da aka yi amfani da shi a cikin aikin masana'anta na speculum na farji. Abubuwan da ake amfani da su a cikin farji kayan aikin likita ne da ake amfani da su a lokacin gwajin mata don buɗewa da riƙe bangon farji. Ana amfani da gyaggyarawa don samar da speculum ta hanyar allura kayan da suka dace a cikin rami na mold sannan a ba shi damar ƙarfafawa da ɗaukar siffar abin da za a yi. Ƙirar ƙira ta haɗa da fasali kamar siffa da girman ƙayyadaddun ƙira, tsarin daidaita kusurwar buɗewa, da kowane ƙarin fasali kamar tushen haske don haɓakar gani. Yana da mahimmanci don samun madaidaicin ƙira da ƙira mai kyau don tabbatar da samfurin da aka samar tare da siffar da ake so da kuma aiki.Injecting Material Injection: Da zarar an kafa samfurin, wani abu mai dacewa, sau da yawa wani nau'in filastik na likita irin su polycarbonate, an saka shi a cikin rami na mold. Ana allurar kayan a babban matsin lamba ta amfani da injuna na musamman. Allurar tana tabbatar da cewa narkakkar kayan ya cika kogon gyaɗa gaba ɗaya, yana ɗaukar siffar ƙwanƙolin farji. Kayan aiki da kayan aiki da aka yi amfani da su don wannan tsari na iya bambanta dangane da ƙayyadaddun buƙatu da ma'auni na samarwa.Cooling, Solidification, and Ejection: Bayan da aka yi amfani da kayan aiki, an bar shi don kwantar da hankali da ƙarfafawa a cikin m. Ana iya samun sanyaya ta hanyoyi daban-daban, kamar faranti mai sanyaya ko na'urorin sanyaya zagayawa. Da zarar kayan ya dafe, ana buɗe ƙura, kuma ana fitar da ƙayyadaddun ƙayyadaddun ƙayyadaddun farji. Ana iya sauƙaƙe fitarwa ta hanyoyi kamar fil ɗin fitarwa ko matsa lamba na iska. Ana kulawa da kyau yayin fitarwa don tabbatar da cewa ba a lalace ba. Gabaɗaya, ƙwayar ƙwayar ƙwayar cuta ta farji wani kayan aiki ne mai mahimmanci wajen samar da speculums na farji. Yana ba da damar ingantaccen aiki da daidaiton ƙirar ƙira tare da sifar da ake so, aiki, da inganci. Ana aiwatar da tsauraran matakan kula da ingancin sau da yawa yayin aikin samarwa don tabbatar da samfuran ƙarshe sun cika ƙayyadaddun ƙayyadaddun da ake buƙata kuma suna bin ka'idodin likita.

| 1.R&D | Muna karɓar zanen 3D na abokin ciniki ko samfurin tare da buƙatun cikakkun bayanai |

| 2.Tattaunawa | Tabbatar da cikakkun bayanai game da abokan ciniki: rami, mai gudu, inganci, farashi, kayan abu, lokacin bayarwa, abu na biyan kuɗi, da sauransu. |

| 3. Sanya oda | Dangane da abokan cinikin ku sun tsara ko zaɓi ƙirar shawarwarinmu. |

| 4. Mold | Da farko Mun aika mold zane zuwa abokin ciniki yarda kafin Mu yi mold sa'an nan fara samar. |

| 5. Misali | Idan samfurin farko ya fito bai gamsu da abokin ciniki ba, muna canza ƙirar kuma har sai mun hadu da abokan ciniki gamsu. |

| 6. Lokacin bayarwa | 35-45 kwanaki |

| Sunan Inji | Yawan (pcs) | Asalin ƙasar |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM (Madubi) | 2 | Japan |

| Yanke Waya (sauri) | 8 | China |

| Yanke Waya (Tsakiya) | 1 | China |

| Yanke Waya (a hankali) | 3 | Japan |

| Nika | 5 | China |

| Yin hakowa | 10 | China |

| Latar | 3 | China |

| Milling | 2 | China |